Circuit Breaker Repair Las Vegas | Diagnostic & Replacement Specialists

A breaker that trips repeatedly isn't protecting you—it's warning you of a failure in progress. The reset is temporary. The underlying issue—thermal fatigue, bus bar corrosion, mechanical wear—worsens with every cycle.

Las Vegas breakers endure extreme conditions. AC compressors cycle 4,000+ hours annually. Each startup creates inrush current 5-7 times normal amperage. The breaker's bi-metal strip flexes thousands of times yearly in 145°F garage panels. After a decade, the metal fatigues. The breaker weakens, tripping at 12 amps instead of rated 15. Or worse—it fails to trip during faults, allowing conductors to overheat and ignite insulation.

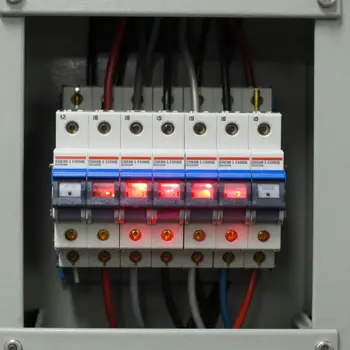

We diagnose the root cause. We measure voltage drop across breaker contacts. We use thermal imaging to identify high-resistance connections. We test trip curves under load. We don't guess.

Diagnosing Breaker Failure in the Southern Nevada Climate

Henderson, Summerlin, and North Las Vegas homes run cooling equipment nearly year-round. Continuous high-amperage loads accelerate breaker degradation. The failure modes we see repeatedly are predictable consequences of desert heat.

Understanding Thermal Fatigue & Nuisance Tripping

Circuit breakers use thermal-magnetic trip mechanisms. A bi-metal strip heats from current flow. When current exceeds rating, the strip bends, releasing a latch. Severe overloads trigger instant magnetic trip.

Thermal fatigue occurs from thousands of heating cycles. AC compressor starts heat the breaker; shutdowns cool it. In Las Vegas, this happens 8-15 times daily May through October. After 10,000 cycles, metal properties change. The breaker trips at 80% of rated capacity—12 amps on a 15-amp breaker.

Nuisance tripping follows. The breaker is failing, not overloaded. Ambient temperature affects trip points. A 15-amp breaker rated at 77°F de-rates in high temperatures. In a 130°F garage panel, it effectively becomes a 13-amp breaker.

Signs of a Failing Main Breaker: Buzzing, Heat, & Odors

Main breakers handle total household current. Excessive heat indicates problems.

Buzzing or humming signals loose connections or degraded surfaces. The sound comes from contacts vibrating at 60Hz through high-resistance points. This is arcing, generating extreme heat and oxidizing contact surfaces.

Hot breakers above ambient indicate current exceeding rating or internal resistance. We measure temperature using infrared thermography. Functioning breakers shouldn't exceed 20°F above ambient. Breakers 40-50°F above are failing.

Burning plastic means insulation is melting from overheated connections. The panel must be de-energized immediately.

Correcting Bus Bar Pitting & High-Resistance Connections

Bus bars distribute power to branch breakers. Each breaker connects via metal "stabs." After decades of thermal cycling, failure modes develop.

Bus bar pitting occurs when high-resistance connections generate heat. Heat oxidizes the bus bar surface. Oxidation increases resistance, generating more heat. Severe pitting prevents proper connection.

We address pitting through panel replacement. Modern panels use tin-plated copper bus bars resistant to oxidation.

High-resistance connections at stabs cause similar problems. We identify these through thermal imaging—hot spots 30-50°F above surrounding temperatures. Correcting requires cleaning oxidized surfaces, tightening connections, or replacing panels.

Obsolete Panels: The Zinsco & Federal Pacific Danger

Certain panel manufacturers produced equipment with documented failure modes. Federal Pacific Electric (FPE) and Zinsco panels dominate 1960s-1980s Las Vegas construction. These panels kill people. The failures aren't rare anomalies—they're predictable outcomes of design defects.

Why Stab-Lok Breakers Fail to Trip

Federal Pacific Electric Stab-Lok breakers have documented failure rates exceeding 25%. The breakers fail to trip during overloads. This is inherent design.

FPE breakers use thin metal stabs that deform when inserted. Thermal cycling loosens connections. Heat further deforms stabs. Eventually the breaker loses bus bar contact.

When fault current flows, the trip mechanism activates but contacts don't fully open because deformed stabs interfere. Current continues through the partially-open breaker, creating extreme heat. The breaker melts. Bus bars melt. Fires start.

Federal Pacific panels must be replaced. There is no "repair" option.

Identifying Melted Bus Bars in Sylvania/Zinsco Systems

Zinsco panels use aluminum bus bars contacting aluminum stabs. Aluminum-to-aluminum connections oxidize aggressively with heat.

The oxidation creates insulating layers generating heat. The heat melts the aluminum bus bar. We regularly find Zinsco panels where the bus bar melted through at breaker connections.

Melted bus bars create arcing faults generating 3,000°F+ temperatures. Panel enclosures melt. Adjacent framing ignites.

Zinsco panels must be replaced. Paradise, Winchester, older Henderson, and Spring Valley contain thousands still in service.

Compliance with the 2026 Clark County Electrical Code

Clark County adopted the 2023 NEC effective January 11, 2026. This adoption introduced mandatory requirements affecting breaker replacement and panel repairs.

Mandatory Surge Protection (SPD) for Service Upgrades

NEC 230.67 requires Type 1 or Type 2 SPDs on all services. Enforceable in Clark County since January 11, 2026. Any work on distribution equipment—panel replacement, main breaker replacement—triggers SPD requirement.

Valley grid experiences transients from utility switching, monsoon lightning, and motor startups. Type 1 SPDs install on line side of main breaker. Type 2 on load side. We install SPDs rated 40kA minimum, higher (50-80kA) for comprehensive protection.

SPD installation adds $300-$600 but prevents thousands in damage.

AFCI Protection Requirements for Modern Circuit Integrity

AFCI protection expanded under 2023 NEC. All 15-amp and 20-amp circuits require AFCI, including lighting, living areas, and kitchens.

Arc-fault interrupters detect dangerous arcing standard breakers cannot. Series arcing occurs when conductors develop breaks. Parallel arcing occurs when conductors short through insulation. Both ignite insulation.

AFCI breakers analyze current waveforms. Arcing creates distinct signatures. The processor trips before ignition heat develops.

Dual-function AFCI/GFCI provide both protections for kitchens, bathrooms, and laundry. Cost is $45-$60 versus $8-$12 for standard breakers.

FAQ: Circuit Breaker Troubleshooting & Safety

Why does my breaker feel hot to the touch?

Breakers generate heat from normal current through I²R losses. However, breakers should not feel hot—warm at most, matching surrounding panel temperature. A hot breaker indicates: (1) Current exceeding rating, (2) High-resistance connection at stabs, or (3) Internal degradation from thermal fatigue. We measure actual current, inspect connections for oxidation, and test breaker functionality. Hot breakers are failure warnings. Continued operation risks fire. Do not ignore hot breakers.

Can I just replace a 15-amp breaker with a 20-amp if it keeps tripping?

No. Breaker ratings must match wire capacity. A 15-amp breaker protects 14 AWG wire rated for 15 amps. Installing a 20-amp breaker on 14 AWG wire allows 20 amps through conductors rated for 15, overheating wire and starting fires. The breaker protects the wire, not appliances. If your 15-amp breaker trips repeatedly: (a) Circuit is overloaded requiring redistribution or new circuits, or (b) Breaker is failing requiring replacement with another 15-amp. We never oversize breakers relative to wire gauge.

What does the 2026 code say about replacing old breakers?

The 2023 NEC adopted January 11, 2026, requires surge protection (Type 1 or Type 2 SPD) during service equipment modifications, including panel or main breaker replacement. For branch breaker replacement, code doesn't require full upgrades, but we install AFCI breakers meeting current requirements. If replacing breakers in Federal Pacific or Zinsco panels, individual replacement is not recommended—these panels have fundamental design defects requiring complete replacement. Modern breaker replacement must use compatible breakers for the panel manufacturer and bus bar. Incompatible breakers create dangerous conditions even if they physically fit.